410 430 stainless steel pipe

Stainless steels are steel alloys that contain more than 10.5% chromium with excellent corrosion resistance. Chromium reacts strongly with oxygen to form a very thin, invisible, stable oxide film on the surface of the stainless steel. This film is called the passive layer and forms rapidly in ordinary atmospheres. If it is damaged, the film usually heals spontaneously. It is this passive layer that gives stainless steel its corrosion resistance.

The stainless steels can be divided into five groups – austenitic, ferritic, duplex, martensitic and precipitation hardening. Each group has different dominant characteristics, and there are several grades within each group.

Austenitic stainless steels are easy to work and weld, and have excellent ductility, toughness and corrosion resistance with good strength. They contain 17 to 25% chromium and 8 to 20% nickel, and may contain other elements to achieve the desired properties. The most common extra element is molybdenum, which greatly improves corrosion resistance. Austenitic stainless steels are usually used in the annealed condition, when they have a useful range of mechanical and physical properties. Strength can be increased by cold working, but not by heat treatment. Welding of this stainless steel grade is straightforward, although welding procedures are a little different to those used for carbon steel. Austenitic stainless steels are non-magnetic in the annealed condition, but will become slightly magnetic when cold worked.

Advantage

Corrosion Resistance

Alloy 410 stainless steel plate is resistant to atmospheric conditions, water and some chemicals. It can be used in environments containing weak or diluted acetic acid, naptha, nitric acid and sulfuric acid. The alloy is also resistant to acids contained in foods.

410 stainless steel plate can also be used in slightly chlorinated and desaereted water. It performs well in oil and gas applications where desaereted and low hydrogen sulfide exist. However, the alloy is prone to chloride attack, particularly in oxidizing conditions.

410 stainless steel plate stainless steel plate operates well in environments requiring moderate corrosion resistance and high mechanical properties.

Oxidation Resistance

Alloy 410 stainless steel plate resists oxidation up to 1292°F (700°C) continuously, and up to 1500°F (816°C) on an intermittent basis.

Product Details

Ferritic stainless steels have similar strength, ductility and fabrication characteristics to carbon steels, with much better corrosion resistance. This group contains grades with 10.5% up to 22% chromium, which do not have the nickel addition made to austenitic grades. The amount of chromium controls the corrosion resistance, and there are some special grades where there is an extra addition of molybdenum. The limitation of the ferritic grades is that welds in some grades lack toughness, and they are rarely used in structural applications – hence they are mainly available as sheet and coil up to about 1.6 mm in thickness. Ferritic grades canot be strengthened by heat treatment, and are not much strengthened by cold work, so they are usually used in the annealed condition. All the ferritic grades are magnetic in all conditions.

409 Grade 409 is a utility grade of stainless steel containing about 10.5% of chromium. It is mainly used in automotive exhaust systems, and other applications where appearance is not important. The surface soon stains, but the rate of metal loss is much lower than with carbon steel.

430 Grade 430 is the most common ferritic stainless steel, used for mild indoor environments, dishwasher liners and automotive trim. It contains 17% of chromium, and hence the corrosion resistance is a little less than that of grade 304. In architectural applications it is usually only used indoors.

410 steel contains the minimum amount of chromium to impart stainless steel properties. 410 stainless steel resists oxidation and scaling up to 1200 °F. Hardness is one of 410 stainless steel's best features; It resists abrasion and wear better than most 300 series stainless steels.

Product Parameters

| Chemical Material Composition of SS 410 seamless pipes | ||||||||||

| Grade | Ni | Mn | P | C | S | Si | Cr | Mo | N | |

| 410 | min. | – | – | – | – | – | – | 11.5 | – | – |

| max. | 0.75 | 1 | 0.04 | 0.15 | 0.03 | 1 | 13.5 | |||

| SS 410 Seamless Pipes Mechanical Properties | |||||

| Tempering Temperature (0C) | Tensile Strength (MPa) | Impact Charpy V (J) | Elongation (% in 50mm) | Yield Strength 0.2% Proof (MPa) | Hardness Brinell (HB) |

| Annealed * | 480 min | – | 16 min | 275 min | – |

| 204 | 1310 | 30 | 16 | 1000 | 388 |

| 316 | 1240 | 36 | 14 | 960 | 325 |

| 427 | 1405 | # | 16 | 950 | 401 |

| 538 | 985 | # | 16 | 730 | 321 |

| 593 | 870 | 39 | 20 | 675 | 255 |

| 650 | 755 | 80 | 23 | 575 | 225 |

Product Name | Stainless steel tube / pipe |

Type | Seamless or Welded |

Material (ASTM) | 201 202 304 304L 309s 310s 316 316L 316TI 317L 321 904L S32205/custom |

Material (DIN) | 1.4301 1.4306 1.4541 1.4401 1.4404 1.4571 1.4539 1.44621.4410 1.4833 1.4845 |

Outter Diameter (OD) | 3-1220mm/custom |

Thickness | 0.5-50mm/custom |

Length | 6000mm 5800mm 12000mm or Customized |

Surface Finished | No.1 No.3 No.4 HL 2B BA 4K 8K 1D 2D |

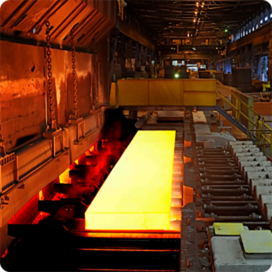

Technique | Cold Drawn or Hot rolled |

Standard | ASTM AISI DIN JIS GB EN |

Application | Construction, Industry, decoration and foodstuff etc. |

Monthly Supply | 5000 Tons |

Delivery Time | 7-10 Working Days after Deposit |

Package | Plywood Case/Pallet or Other Export Package Suitable for Long Distance Shipping |

End/Edge | Plain Mill |

Service | OEM/ODM service |

Product catalogue

Product catalogue

Hot Products

Hot Products

Request a Quote

TISCO Steel is a comprehensive enterprise integrating steel trade, processing. Providing one-stop service for global customers. Complete specifications,Export to the world, Factory direct sales, Integrity management. Meet all your steel needs!

Strong technical force.

Sophisticated production equipment.

Strict quality control procedures assuring the highest quality products.

Professional technical team and experienced project management team.

Inventory large shipment loss ah, price concessions complete specificationsto meet all your steel needs.

We are a well known worldwide exporter of Aluminum coils, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

| 302 stainless steel pipe | 316 stainless steel pipe |

| 304 seamless stainless steel pipe | 316l stainless steel pipe supplier |

| 304 stainless steel 3 inch pipe | 317 stainless steel pipe |

| 304 stainless steel pipe supplier | 317l stainless steel pipe |

| 304 stainless steel pipe suppliers | 321 stainless steel pipe |

| 304 stainless steel seamless pipe | 321 stainless steel pipe supplier |

Tianjin TISCO has extensive industry experience, an expert staff, and state-of-the-art equipment. Our team ensures your material meets your exact specifications and is delivered just when you need it.

Tel: +86 13370586666

Tel: +86 13370586666  E-mail:[email protected]

COPY

E-mail:[email protected]

COPY

Leave a message

Leave a message