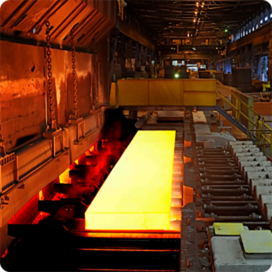

high strength steel plate

High strength steel can be classified into various types based on its chemical composition and usage.

Firstly, low alloy high-strength steel, which is mainly composed of elements such as carbon, manganese, and silicon, has high strength and toughness, and is widely used in fields such as automobiles, buildings, and bridges.

Next is high-strength low alloy steel, which is mainly composed of elements such as carbon, manganese, silicon, and chromium. It has higher strength and toughness and is suitable for manufacturing large machinery, ships, bridges, and other engineering projects.

Advantage

There are many advantages of high-strength plates. Firstly, their strength is very high, much higher than that of ordinary steel plates. They can withstand greater loads and pressures, making the building structure more stable and safe. The toughness of high-strength plates is also very good, which can prevent them from breaking easily under impact or compression, thus protecting the safety of buildings. Moreover, the wear resistance and corrosion resistance of high-strength plates are also excellent, able to withstand tests in harsh environments and maintain a long service life.

The application range of high-strength plates is very wide, and they can be applied in fields such as architecture, machinery, automobiles, aerospace, etc. In the field of construction, high-strength slabs are mainly used for manufacturing bridges, supporting structures for buildings, underground pipelines, and oil tanks; In the field of machinery, high-strength plates are mainly used for manufacturing trucks, excavators, milling machines, and stamping machines; In the automotive field, high-strength plates are mainly used for manufacturing the body and chassis of automobiles; In the aerospace field, high-strength plates are mainly used for manufacturing aircraft fuselage and engine components.

In short, high-strength panels, as a very important building material, have many advantages and application fields. Its strength, toughness, wear resistance, and corrosion resistance are all excellent, which can ensure the safety and service life of buildings. If you need to build bridges, buildings, mechanical equipment, or cars, you may consider using high-strength boards as building materials. I believe it will definitely bring good results to your project.

Product Details

High strength plate realizes Solid solution strengthening, grain boundary strengthening and second phase strengthening of the matrix structure by adding different alloy elements. Low alloy Martensite steel, bainite steel, austenite/Bainite dual phase steel, Martensite/Bainite dual phase steel, etc. have successively appeared. In recent years, with silicon as the main alloying element, silicon strongly inhibits carbide precipitation during Bainite transformation.

The austenite bainite dual phase structure composed of carbide free Bainite ferrite and residual austenite stabilized by carbon and silicon can be obtained. Because carbide free eliminates the cause of crack or spalling, it has excellent comprehensive mechanical properties of strength and toughness, and is the most popular new generation of wear-resistant materials in the world at present. It has the following advantages: high yield strength, tensile strength, and good ductility.

High strength and high Fracture toughness; High impact strength; Excellent wear resistance. High strength wear-resistant steel undergoes a special heat treatment process, which combines high strength and toughness with good forging workability. The wear resistance is more than twice as high as that of high manganese steel and high chromium steel. The ultra-high strength wear-resistant steel was modified and alloyed by rare earth, and nano Bainite/Martensite multiphase structure was obtained through certain process treatment.

Its tensile strength reaches 1950 MPa, elongation after fracture is 17%, reduction of area is 38%, HRC55, Aku72J, and its comprehensive strength and toughness properties are excellent. It has great theoretical research value and application promotion value for strengthening and toughening. This steel has excellent mechanical processing performance, forging performance, and welding performance. After isothermal quenching treatment, the strength plastic accumulation reaches 51 GPa. High strain rate deformation ballistic tests indicate that.

The characteristics of high-strength plates are mainly applied to environmental components such as mining, construction machinery, and strong wear and tear; Open pit mining shovel teeth, bucket teeth, excavator factory supporting shovel teeth, etc; Vehicles, railway tracks, power, communication, mechanical equipment, mining machinery, cutting teeth, hydraulic equipment, transmission equipment, high-strength standard parts, etc; High strength bolts, wear-resistant wire mesh, coastal bridge reinforcement, and high-strength equipment.

Product Parameters

| Steel Grade | Quality Level | C % (≤) | Si % (≤) | Mn (≤) | P (≤) | S (≤) | Nb (≤) | V (≤) | Ti (≤) | Cr (≤) | Ni (≤) | Cu (≤) | N (≤) | Mo (≤) | B (≤) | Als (≥) |

| Q390 | Q390A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.07 | 0.20 | 0.20 | 0.30 | 0.50 | 0.30 | 0.015 | 0.10 | – | – |

| Q390B | 0.035 | 0.035 | – | |||||||||||||

| Q390C | 0.030 | 0.030 | 0.015 | |||||||||||||

| Q390D | 0.030 | 0.025 | 0.015 | |||||||||||||

| Q390E | 0.025 | 0.020 | 0.015 |

| Thickness or Dia. (Ø) mm; Yield Strength (≥N/mm2) | ||||||||||

| Steel Grade | Quality | Ø≤16 | 16< Ø ≤40 | 40 < Ø ≤63 | 63 < Ø ≤ 80 | 80 < Ø ≤ 100 | 100 < Ø ≤ 150 | 150 < Ø ≤ 200 | 200 < Ø ≤ 250 | 250 < Ø ≤ 400 |

| Q390 | Q390B | 390 | 380 | 360 | 340 | 340 | 320 | – | – | – |

| Q390C | ||||||||||

| Q390D | ||||||||||

Product Name | carbon steel plate |

Standard | JIS/ASTM/DIN/EN |

Thickness | 0.1mm-300mm Or Customized |

Width | 500-2250mm |

Length | 1000mm-12000mm or Customized |

Tolerance | Thickness: +/-0.01mm, Width:+/-1mm |

MOQ | 5 Tons |

Application | 1.Automobile, Bridges, Buildings. |

Package | Standard export package or customized |

Capacity | 1000000 tons /month |

Mill MTC | Supply |

Product catalogue

Product catalogue

Hot Products

Hot Products

Request a Quote

TISCO Steel is a comprehensive enterprise integrating steel trade, processing. Providing one-stop service for global customers. Complete specifications,Export to the world, Factory direct sales, Integrity management. Meet all your steel needs!

Strong technical force.

Sophisticated production equipment.

Strict quality control procedures assuring the highest quality products.

Professional technical team and experienced project management team.

Inventory large shipment loss ah, price concessions complete specificationsto meet all your steel needs.

We are a well known worldwide exporter of Aluminum coils, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

| 1045 carbon steel plate density | carbon steel plates prices |

| 1050 carbon steel plate prices | carbon steel plates quotes |

| 1074 carbon steel plate louisville | carbon steel plates specifications |

| 1095 carbon spring steel shim plate | high carbon steel plate pricelist |

| 1095 carbon steel plate prices | high carbon steel plates |

| 10mm carbon steel plate weight | High Quality Carbon Structural Steel Plate |

Tianjin TISCO has extensive industry experience, an expert staff, and state-of-the-art equipment. Our team ensures your material meets your exact specifications and is delivered just when you need it.

Tel: +86 13370586666

Tel: +86 13370586666  E-mail:[email protected]

COPY

E-mail:[email protected]

COPY

Leave a message

Leave a message