Q195/S195/A53 GRADE A

ASTM A36 is a structural quality carbon steel for use in welded, bolted or riveted construction of bridges and buildings, and for general structural purposes. Minimum yield strength of 36 KSI (250MPa) is required to meet the requirements of A36. ASTM A36 plate is used in a variety of applications, which include, but are not limited to: railroad cars, trucks, agriculture equipment, trailers, construction equipment, buildings and bridges.

– Available in: Hot Roll or Hot Roll Pickled & Oil

A 1011-F HSLAS GR50/GR80 – This specification covers sheet hot-rolled, carbon, structural, high-strength low-alloy with improved formability, and strip, in coils and cut lengths. The addition of alloying elements raises the yield point, offering higher strength-to-weight ratios. The product is intended for applications where higher strength, savings in weight, improved formability and weldability are important.

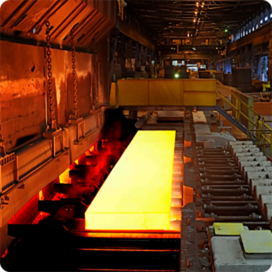

Hot Rolled Carbon Steel Process

The first step in the hot rolling process is to heat the steel, element, or mineral mixture to intense heat above its recrystallization temperature. Once it is heated above this point, the steel becomes malleable. It is then fed into rolling machinery, where it can be shaped and easily formed. This hot-rolled carbon steel process allows for the ability to produce large quantities of steel in a single batch as minimal additional processing is required.

After the carbon steel is processed, it is then cooled to room temperature, which normalizes it. The heating and slow cooling process of steel alter the microstructure of the metal, which increases its ductility and strength. When forming steel, enhanced ductility is an important factor in obtaining its required shape. The exact mix of additional elements to the iron content determines the grade of the steel and its unique strength, forming, and hardness characteristics. Carbon and manganese are the two primary additional elements that influence the outcome of the particular grade of material, but other elements can play a key role as well.

Additionally, hot rolled steel shrinks slightly during the cooling phase, resulting in slight variations in the exact thickness and width of the coil. The finished product will not always meet the specific target that was originally intended. For this reason, there are industry-defined standard tolerances and ranges for flat-rolled steel products. Production of hot-rolled steel is both an art and science that truly requires a delicate balance. Oftentimes, additional and readily available processing is necessary for areas where tight tolerances are essential.

Three D Metals offers three steel products: high carbon steel, low carbon steel and stainless steel. High carbon steel is beneficial for resisting abrasion and retaining shape. Low carbon steel is easier to machine and weld due to its greater ductility. Stainless steel is less likely to rust when installed in wet environments and its durability can vary greatly depending on its grade.

Application

Carbon hot-rolled steel plates are used in the construction sector and for welding such as cantilever cranes, construction equipment, railway tracks, agricultural equipment and heavy vehicle frames.By varying the content of carbon steel, different qualities of steel can be produced.In general, the higher the carbon content in steel, the more brittle, the harder, and the less tough the steel is.

Product Parameters

Product Name | Carbon Steel Sheet Coil |

Standard | AiSi, ASTM, BS,GB |

Material | A32, AH32,A36,AH36,DH36,D32 DH32 Q195 Q215 Q235 Q345 SS490 SM400 SM490 SPHC SPHD SPHE SPHF SEA1002 SEA1006 SEA1008 SEA1010 |

Technology | Cold Rolled Hot Rolled |

Length | 1-100mm or customized |

Width | 600-3000mm or customized. |

Thickness | 0.1-300mm or customized. |

Surface | natural color,iron gray (low carbon plate), brown (special alloy plate, the high carbon plate), partial ochre (weather resistance), with temperature oxidation pattern, than manufacture rough surface |

Price Item | FOB、CIF、DDU、FCA、EXW ,.etc |

Certificate | ISO:9001-2015, CE,SGS |

Advantage | We have stock about 20000 tons |

Quality Assurance | 1.Provide MTC (Mill Test). 2.Accept the inspection by the third party agent |

Product catalogue

Product catalogue

Hot Products

Hot Products

Request a Quote

TISCO Steel is a comprehensive enterprise integrating steel trade, processing. Providing one-stop service for global customers. Complete specifications,Export to the world, Factory direct sales, Integrity management. Meet all your steel needs!

Strong technical force.

Sophisticated production equipment.

Strict quality control procedures assuring the highest quality products.

Professional technical team and experienced project management team.

Inventory large shipment loss ah, price concessions complete specificationsto meet all your steel needs.

We are a well known worldwide exporter of Aluminum coils, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

| carbon steel coil factories | carbon steel coil nails factories |

| carbon steel band saw blade coil stock | carbon steel coil nails |

| best hr carbon steel coil | carbon steel coil manufacturers in china |

| astm a36 coil carbon steel | carbon steel coil manufacturers |

| alloy carbon steel coil | carbon steel coil manufacturer |

| hot rolled carbon steel coil manufacturer | carbon steel coil in stock |

| custom low carbon steel coil | carbon steel coil for sale |

| custom hot rolled carbon steel coil | carbon steel coil factory |

Tianjin TISCO has extensive industry experience, an expert staff, and state-of-the-art equipment. Our team ensures your material meets your exact specifications and is delivered just when you need it.

Tel: +86 13370586666

Tel: +86 13370586666  E-mail:[email protected]

COPY

E-mail:[email protected]

COPY

Leave a message

Leave a message