2022-01-14

Processing standard of 316l stainless steel plate

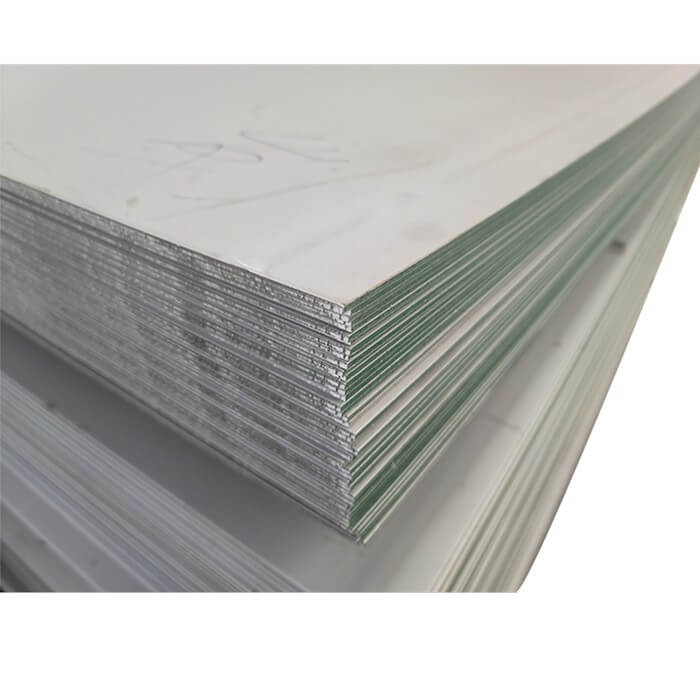

The 316l stainless steel plate has a high safety factor, and the two-layer composite type is more wear-resistant, ensuring strong industrial production. 316l stainless steel plate production and manufacturing technical workers safety practical operating guidelines. 316l stainless steel plate safety production technical machinery and equipment safety and safety operating procedures. The high incidence of safety accidents and preventive measures during the work of 316l stainless steel plate engineering projects.

In the case of production and processing of 316l stainless steel plate, as far as the refrigerant lubricant is concerned, it can reduce the drilling heat and cutting speed in the drilling process. For the production and processing of 316l stainless steel plates, in the case of opening holes, it is necessary to pay attention to the refrigerant that can only be considered when working with all-grinding drills.

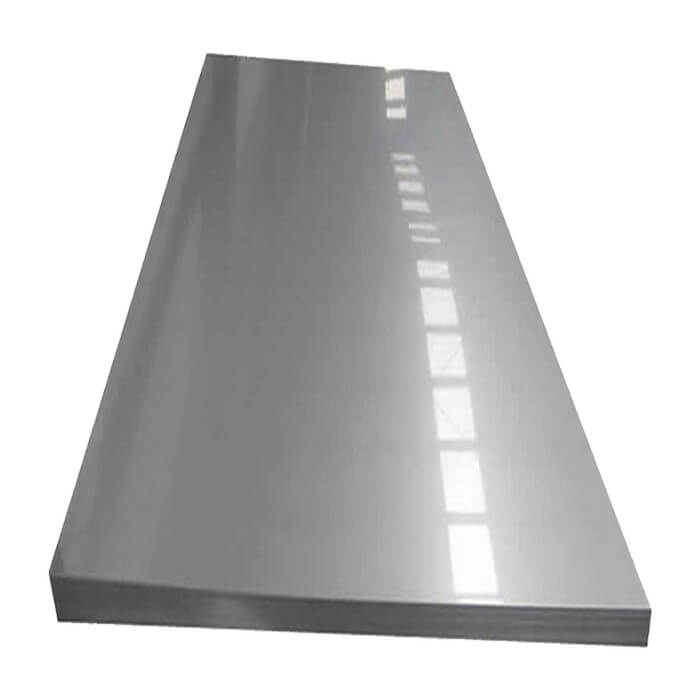

The standard surface production and processing of 316l stainless steel plate means that there will be many kinds of surface production and processing. The surface layer of 316l stainless steel plate is produced and processed after hot rolling, quenching, pickling passivation and descaling. For other stainless steel plates, the processing technology is basically the same as the above processing technology, and the surface layer will be slightly shiny. At this moment, it is possible to carry out the relevant grinding and polishing solution.

Tianjin TISCO has extensive industry experience, an expert staff, and state-of-the-art equipment. Our team ensures your material meets your exact specifications and is delivered just when you need it.

Tel: +86 13370586666

Tel: +86 13370586666  E-mail:[email protected]

COPY

E-mail:[email protected]

COPY

Leave a message

Leave a message