-0001-11-30

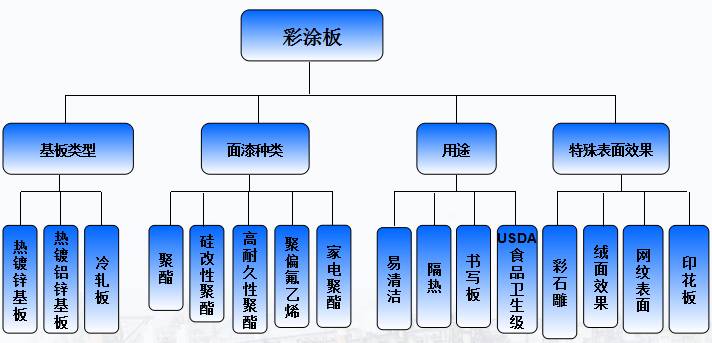

Substrate type | Characteristic | application |

|---|---|---|

Cold rolled steel sheet | Its corrosion resistance is poor and the cost is low. | Lining parts, lamps, wire boxes, etc. of metal furniture |

Hot dip galvanized | The zinc layer of hot-dip galvanized sheet is thick, which is suitable for preparing color coated sheet with high corrosion resistance and low decorative requirements. | Exterior wall panel, roof panel, garage door, etc |

Hot dip aluminized zinc steel plate | The production process is basically the same as that of hot-dip galvanized sheet, mainly regulating the composition of molten plating solution, which is classified according to the aluminum content. | Outdoor environment with strong corrosivity |

1. Alkyd resin coating Alkyd resin is made by polycondensation of polyols, polybasic acids and fatty acid esters. Its properties are closely related to the types of modifieTheir characteristics are as follows:

(1)It has good flexibility, adhesion and mechanical strength.

(2)The pigment has good dispersibility in the coating.

(3)The coating has good durability and light retention.

(4)The paint film is full, with good solvent resistance and heat resistance, but poor water resistance.d vegetable oils and the length of oil content. There are many kinds of alkyd resins.

The coating is widely used in construction doors and windows, wooden furniture, ships, bridges, mechanical and electrical products, optical instruments, various car boxes, etc.

2. Acrylic resin coating Acrylic resin is polymerized from acrylic acid or methacrylate, acrylic acid, amide and other monomers. Due to different monomers, thermoplastic and thermosetting coatings can be made.

Thermoplastic coating has good hardness, light color without yellowing, and good durability. It is mainly used for aluminum alloy surface with good weather resistance and light retention required by the aviation industry.

Thermosetting coatings have excellent physical and mechanical properties, good surface fullness, strong weather resistance, good color retention, high brightness, high hardness, and certain water and oil resistance. Most of them are cured by baking at high temperature. It is applicable to cars, light industrial products, household appliances, etc.

3. Polyester resin coating Polyester resin is polymerized mainly consisting of diols and dicarboxylic acids. Polyester containing coatings can obtain a variety of combinations of physical properties, that is, both hardness and flexibility. They also have excellent chemical resistance, heat resistance and good formability. They are mainly used for building linings, carriers, etc.

4. Silicon modified fine paint is composed of acrylic acid or polyester and silicification. It has good surface durability, no chalking and gloss retention. Although limited in flexibility, they are suitable for general medium roll forming used in construction. Typical use is for external occasions, especially for prefabricated industrial buildings and residential side walls.

5. Phenolic resin coating

Phenolic resin coating is one of the widely used varieties in coatings. It can be divided into modified phenolic resin coatings (such as rosin modified phenolic resin) and pure phenolic resin coatings.

(1) Modified phenolic resin coating: phenolic condensation polymer made of phenol and aldehyde is cyclized with unsaturated rosin acid, and finally the carboxyl group of rosin acid is esterified with glycerol to obtain rosin modified phenolic resin. It has good dryness, durability and water resistance, and is widely used in furniture, doors and windows.

(2) Pure phenolic resin coating: prepared by condensation polymerization of formaldehyde with p-alkyl or p-aryl substituted phenols. It has good water resistance, chemical corrosion resistance and weather resistance, and can be used for ship, aircraft, electrical insulation, etc. The above two coatings can be soluble in organic solvents such as aliphatic hydrocarbons, aromatic hydrocarbons, turpentine, etc.

6. Epoxy resin coating The molecular structure of epoxy resin contains epoxy group. The commonly used epoxy resin is a polymer compound formed by condensation of epoxy chloropropane and diphenylpropane under the action of alkali, which is called bisphenol A epoxy resin for short. It has a linear structure, and can be cross-linked and solidified into a film by adding amine, organic acid, anhydride and other synthetic resins. Bisphenol A epoxy resin has strong adhesive force due to the attraction and chemical bond formed by polar groups such as hydroxyl, epoxy and ether bond in its structure. In addition, it has good chemical stability, alkali resistance, organic solvent resistance, high toughness and mechanical strength. Epoxy resin has high volume resistance and breakdown voltage, so its electrical insulation is good. Epoxy paint is often used as primer.

7. Fluorocarbon coating This is a precious coating with outstanding combination characteristics, including formability, color retention, powder resistance and solvent resistance. These coatings have medium glossiness, and the color range produced is limited. The typical coatings are building wall skin, roof, curtain wall and housing side wall.

8. Fluorocarbon/acrylic acid/polyester mixed coating These coatings have the economy of acrylic acid and polyester and outstanding performance of fluorocarbon resin. They have good manufacturing characteristics and can be exposed to medium corrosive environment for a long time. It is commonly used in the side wall and partition wall of residence.

9. Polyvinyl chloride plastic sol is mostly used in situations where the appearance is required to be durable and durable, and can provide long-term weather resistance and be resistant to handling scratches. This is a multi-purpose material. Its typical uses are wall skin, roof, partition, shelf, electrical component box, flat plate, wing reflector, etc. In general, the plastic sol coating can also be laminated according to user requirements.

10. Polyvinyl chloride organic sol has excellent formability and good decoration, and is also relatively wear-resistant. It is usually applied in a thickness of 40-60um/side, and the maximum thickness can reach 100um/side. Its typical use is for deep drawing parts such as paraffin containers, lawn mower covers, and protective linings and gaskets of metal containers. It is composed of PVC, softener and solvent, and can be stuck firmly with a special primer.

11. Peelable paint

This is a temporary coating. It is widely used to protect high gloss coated plates during manufacturing, processing and transportation. They protect the surface against scratches and serve as a positive marking during forming, assembly and decoration (this paint is only used for the positive side). They often remain on the product until it is sent to the end user to ensure a fresh appearance. It is usually used as the protection of exterior building parapet and side wall panel for forming and shearing at the construction site, as well as for automobile decoration, household appliances and various other products.

12. Weldable zinc rich primer

These coatings have the properties of weldability, especially for the welding and forming properties required by the automobile industry. The average thickness of the film is 15um when the deformation and corrosion resistance requirements are met.

Silicon modified polyester color coating products (SMP):

Features: Special silicone polyester resin and cross-linking agent are used to ensure adequate weather resistance; Use super weather resistant pigment to ensure the permanent brightness of the color; The special silicone structure makes the coating harder, can increase the wear resistance and metal scratch resistance, and can withstand the stamping during processing.

High durability polyester color coating product (HDP):

The use of high-performance polyester resin and inorganic ceramic pigments can achieve many colors that PVDF cannot do; Special polyester structure, good hydrolysis resistance, use of weather resistant pigments, compared with ordinary polyester coatings, has excellent chemical resistance and durability; Compared with the ordinary silicon modified polyester, it has better processability and chemical resistance.

Polyvinylidene fluoride (fluorocarbon) color coating products (PVDF):

More than 70% fluorocarbon resin content makes the coating have good weather resistance, acid and alkali resistance and environmental pollution resistance; All the coatings are made of advanced inorganic ceramic pigments, which block ultraviolet rays and enable the coatings to maintain luster and color; It also has excellent mechanical properties: for example, T-bend can reach 0-2T.

Polyester color coating products for household appliances (JJ):

Note: Except for the panels for solar water heaters, color coated household electrical panels are all environmentally friendly products complying with ROHS directives.

Classification and characteristics of color coated products for household appliances

Type | Example | Features |

|---|---|---|

Cold appliances | Refrigerator, freezer, air conditioner | Hardness, abrasion resistance, pollution resistance, foaming ability and formability |

Thermal appliances | Microwave oven, bread maker | Pollution resistance and thermal stability |

Wet electrical appliances | Washing machine, dishwasher | Anti detergent, anti pollution, flatness |

Dry electrical appliances | DVD, TV backplane | Uniformity of surface particles, scratch resistance, punching formability |

Outdoor household appliances | solar heater | Corrosion resistance, paint film uniformity |

Easy to clean color coating products: ensure that outdoor buildings are clean without obvious rain traces after being washed by rainwater.

Comparison of contamination test by carbon black method

Water and carbon black (95/5 weight ratio) are mixed and dispersed to pollute the coating surface. After drying at 60 ℃ for 1h, the difference △ E before and after the test is detected after the pollutants are washed in running water.

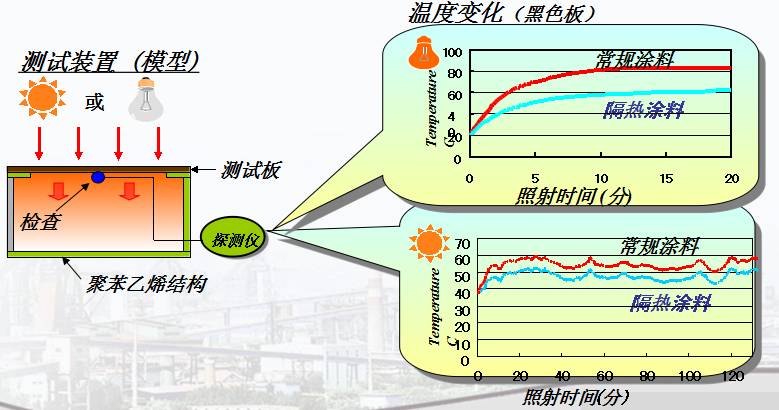

Thermal insulation color coating products: high reflectivity, good weather resistance, good pollution resistance, reducing the indoor temperature by 3-5 ℃, improving the quality of life, saving energy, and extending the service life of color coated boards.

Special surface effect

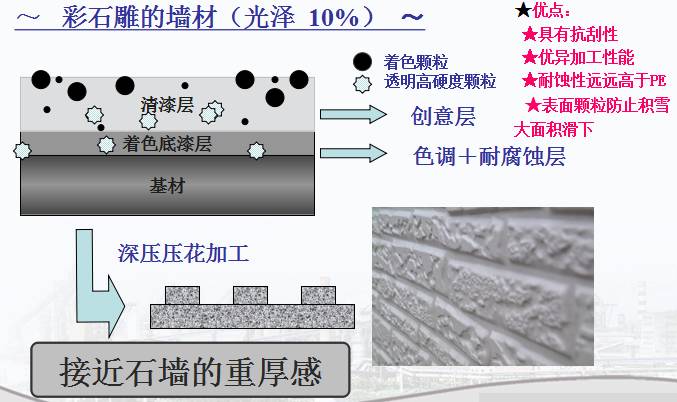

Colored stone carving and painting products:

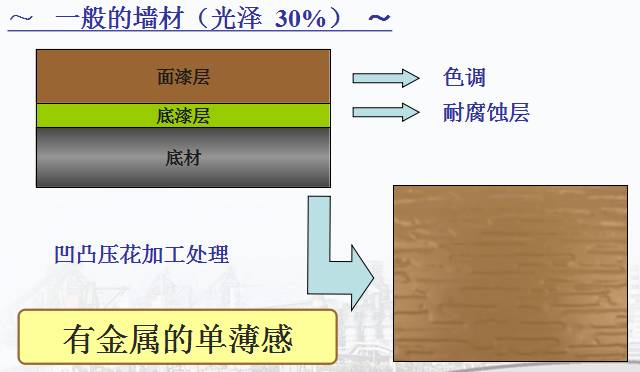

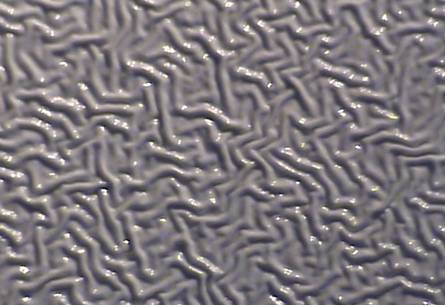

Suede effect color coating products: belong to ordinary polyester system, with low gloss (0-10%) surface and unique wrinkle like appearance surface. Used for interior door panel (for decoration).

Textured effect color coating products: Textured products with their unique appearance and beautiful microstructure, whether used for indoor decoration or outdoor use, will give the existing market a new development and growth point. Its film forming mechanism: during the film forming process of the top coat, the condensation effect of surface tension will occur by controlling the furnace temperature and wind speed to produce a textured effect with a feel.

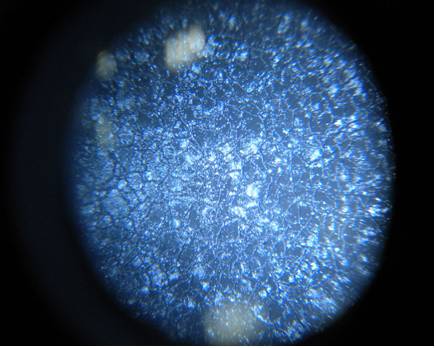

Printing color coating products: printing color coating products are one of the representatives of high-end products, and have begun to gradually replace the traditional PVC film, completely solving environmental problems. Its products adopt a special roller coating process to produce continuous colored patterns, which are widely used in the building decoration industry. They can be used as interior wall panels, ceilings, doors and windows, etc.

Shandong Kuai Ma Steel Co., Ltd. is located in Liaocheng City in the west of Shandong Province. Mainly produce and process stainless steel products, carbon steel series, color-coated steel and galvanized steel products, honing series and seamless steel pipe series,etc.

Our products have been exported to 30 countries and regions. Europe, USA, Canada, United Kingdom, United Arab Emirates,Russia, Australia, South America, Middle East, Africa, India, etc. and our company has rich experience in freight forwarding,We can export to any country that shipping company can reach.

Sincerely welcome customers from home and abroad to consult and negotiate business, and create a better tomorrow together.

Tianjin TISCO has extensive industry experience, an expert staff, and state-of-the-art equipment. Our team ensures your material meets your exact specifications and is delivered just when you need it.

Tel: +86 13370586666

Tel: +86 13370586666  E-mail:[email protected]

COPY

E-mail:[email protected]

COPY

Leave a message

Leave a message